Samsung, another leading telecommunications company, announced to do mass production of several Recordable Voice Chip after the first 7 Nanometer chip integrated with circuit trial-and-drop lithography (EUV) produced by Asia’s largest voice chip manufacturer.

And Samsung also supports for IP and EDA infrastructure so as to win the battle in the ecosystem competition.

At the Samsung Tech Day held in Silicon Valley this week, Samsung announced that the R & D applied the EUV 7 Nanometer LPP (Low Power Plus) process was completed, formally entered commercial mass production, and would move toward 5nm and 3nm in the future on the basis of such technology.

Samsung also announced to publish a 256-GByte RDIMM based on its 16-Gbit DRAM chip and planned to use a built-in Xilinx FPGA solid-state drive (SSD).

However, the 7 nm commercial mass production is still the highlight of the event, coupled with the company’s internal development of the EUV mask detection system, which does symbolize a development milestone for Samsung.

Compared with its 10 nm node, Samsung’s 7 LPP process can reduce chip area by up to 40%, speed by 20%, and power consumption by 50%.

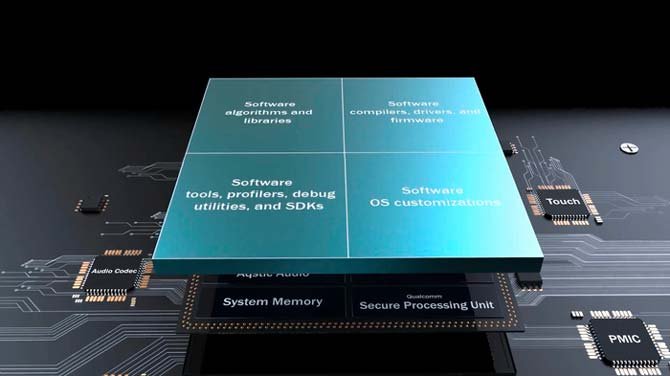

In addition, Samsung said it currently has 50 voice chip manufacturers (surrogate factories) partners, including Antsy, Arm, Cadence (owned a 7 nm digital and analog design process), Mentor, Synopsys and Veri Silicon, all of which have expressed they would apply a 7 nm process for production.

It is said that The 7LPP process has attracted interest from a wide range of customers, including Internet giants, Internet companies, Qualcomm and other mobile phone providers.

However, Samsung is not expecting customers to release relevant information until the beginning of next year.

Samsung’s marketing director Bob Stear said the EUV system has been supporting 250W light sources since Huacheng S3 factory introduced EUV equipment earlier this year. The current power level can increase production to 1500 Wafers/days.

Since then, he said, the EUV system has gradually reached a peak of 280W, and Samsung’s goal is to further increase its power to 300W.

Stear pointed out that EUV requires fewer layers than conventional argon fluoride (ARF) systems requiring a five-layer mask, thus reducing costs and increasing yields.

However, the technology node still needs multiple exposures in the preceding stage (FEOL).

Samsung has developed its own system to compare and adjust expected and actual masks so as to speed up its EUV production. Since it’s not clear whether it’s as automated as a typical third-party detection system, G. Dan Hutcheson, chief executive of VLSI Research, thinks it’s more like a mask inspection system.